- A cowboy walks into a bar, and two steps in he realizes it’s a gay bar.

“What the heck,” he says to himself, “I really want a drink.” When the gay waiter approaches, he says to the cowboy, “What’s the name of your willy?” The cowboy says, “Look, I’m not into any of that. All I want is a drink.

“The gay waiter says, “...I’m sorry but I can’t serve you until you tell me the name of your willy. Mine for instance is called NIKE, for the slogan, ‘Just Do It.’ that guy down at the end of the bar calls his SNICKERS, because ‘It really Satisfies.’ “The cowboy looks dumbfounded, so the bartender tells him he will give him a second to think it over.

So the cowboy asks the man sitting to his left who is sipping on a beer, “Hey bud, what’s the name of yours?” The man looks back and says with a smile, “TIMEX.” The thirsty cowboy asks, “Why Timex?” the fella proudly replies, “‘Cause it takes a lickin’ and keeps on tickin!’”

A little shaken, the cowboy turns to the two fella’s on his right who just happens to be sharing a fruity Margarita and says, “So, what do you guys call yours?” The first man turns to him and proudly exclaims, “FORD, because Quality is Job One.” “Then he adds, “Have you driven a Ford lately?” The guy next to him then says, “I call mine CHEVY…..’Like a Rock!’ “And gives a wink!

Even more shaken, the Cowboy has to think for a moment before he comes up with a name for his manhood. Finally, he turns to the bartender and exclaims, “The name of my willy is SECRET. Now give me a beer.” The bartender begins to pour the cowboy a beer, but with a puzzled look asks, “Why Secret?”

The cowboy says, “Because it’s ‘STRONG ENOUGH FOR A MAN, BUT MADE FOR A WOMAN

All Posts (1994)

As I've got a couple of 6 string guitars on order, I thought I'd tool-up and get some neck pocket templates. I looked at StewMacs...but as well the high price and costly shipping, (and the router bits were even more extortionate) they copped for a lot of very poor reviews, so I decided to look elsewhere. I found something from the EU, with very reasonable shipping, and also got the correct router bit with a bearing from a UK supplier. The bit was really cheap compared with StewMac, so I don't expect it to last long, and I'll have to keep an eye on it for wear, but so far it seems to work OK.

So here's the acrylic template, and after reading about all the problems people had with the StewMac ones I decided to make a working copy in 6mm MDF, keeping the original as a master. A lot of people complained about the Stewmac templates being oversized, but a trial fit seems to show that this one is pretty tight. More worryingly, they said the templates melted under use and ruined the guitars people were working on..so apart from accidentally damaging the perspex one, that was my main reason for making a copy. Of course, what's apparent when you start using this set-up, even just cutting a copy template, is that the router bit gets hot...the heat is transferred to the cutter bearing...and into the template. I was very careful to make light passes to remove the bulk of the MDF, and to let the bit cool right down before actually getting it to run against the template. I reckon that's the key to it...working cool, not letting the bit heat up.

Hopefully this should speed up my builds a bit, and make them more accurate into the bargain. By the way, the three different cutouts are for Strat, Tele and bass necks.

I'm gradually catching up with my backlog of custom work..and here's one of today's jobs...prepping an alu box reso...here it is in the jig just after cutting the soundholes and milling the pickup cutout.

Out of the jig...ready for the next stage.

On the drill press, drilling the coverplate mounting holes.

And into the fiery furnace...for the flame distressing and heat-tempering stage....RESO HELL!!!

And here's the finished article ready for fitting out with the soundwell.

One of these days I will have to finish these projects! Seriously. Fiddle is on the cusp. Hopefully next week for that one. Nickel Seegar parlor guitar parts are mostly here. Should be an "easy" build. And now:

The Monkeypod Elven Lute!

(maybe TWO lutes)

Ok, so they'll probably be 3/4 string dulicimer strummers that LOOK like lutes. Watched "The Court Jester" with Danny Kaye this week and was intrigued by the lute he had with him. It was a three string and looked to be dulcimer-fretted. He didn't really play it but I got the itch to try and make one. I go to ren faires every year and it would be a cool thing to bring.

So I searched eBay for project bowl-back mandolins or lutes. Too expensive. Then I thought I might try searching for 'walnut bowls' because those are turned on a lathe and might make a good lute body. Well I found a gem! (And for just $22 including shipping).

This is a hinged bowl made from monkeypod wood. It's just SHAPED like a walnut. Perfect for a woodsy/elven instrument. It's 16" long x 8" tall so each half is probably around 3-4" deep. The top will definitely be an instrument and if the bottom isn't permanently affixed to the base in a weird way, it will become one too.

I just need to clone myself to make all of these things. There's a Wizard of Oz themed art collective show coming up and I thought I might make a few themed guitars for that too. Keeps me out of trouble I guess.

Hi there! Sorry if I mispelled something, I am learning english.

I am new to the world of the CBG's and well, yesterday I just finish my first cbg and I though it was OK, but then I start to try to learn the basics but it was impossible! I don't get the same sound of all the other cbg's!

I order the CBGITTY starter pack and I just made it, I didn't use the nut and bridge that the pack had because I though it was very high (I play bass and a little guitar so I though it would be very high!). I put the tailpiece in the box, not in the bridge, I don't know how to say that, but for that are the images. I tune in OPEN G and my digital tuner tunes ok, but I think those tuning pegs are just horrible, they don't stay in tune, I THINK, or maybe I am doing something wrong.

It's electro-acoustic with a piezoelectric pickup and electric as acoustic the sound is different from other cbg's around youtube and other places.

- Do you think I must put the bridge and nut from cbgitty?

- The action is low or high?

- My amp is a cbgitty's one, volume and tone, I play acoustic guitar no electric so I bought a nice OLIVA gitty's amp, THAT COULD BE A PROBLEM IN ACHIEVING THE DESIRE SOUND?

- Is pretty dificult to get the OPEN G tuning because a slightly turn in a tuning key and the G or D is GONE!! THE TUNERS COULD BE A PROBLEM?

- What must be the note that goes in the first fret of the neck? Iam getting a B flat in the G's and in the D string an F sustained (I DONT KNOW IS THAT WHAT IS CALLED IN ENGLISH a "bemol" and a "sostenido").

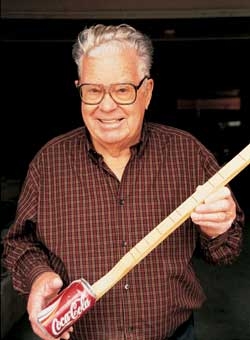

Now building CBGs for some of the most wonderful performers. George Worthmore have been a blues performer all over the word and who's roots are in New York. His is currently in Nashville putting the finishing touches on his new CD. The release party will be on July 28. If you will be in the area...further details will be posted.

Also, Bob Deilman...an amazing Blues artist from Sarasota, Fl. His CD release party was just a fe weeks ago. Packed house and so much appreciation for all involved.

This here stuff is addicting! I told a buddy of mine about cbg's and showed him Mike Snowden's chicken coop video. He told another and now all three of us have built cbg's. One of their girlfriends said he was obsessed... my reply was there are worse addictions to have, at least it isn't a new girlfriend.

I'm a little disappointed that none of my connections on LinkedIn has endorsed my Cigar Box Guitar Skills. :-\

That is all.

c'est un site qui ne manque pas d'humour...

Gday,I need some help!My cousin Jo got a neat clip of me playing my CBG on her phone and put it on Facebook.I would like to put it on my page here,but being a bit Neanderthal with technology,I can't seem to figure out how.Any pointers(preferably simple and in Old School English(I have no kids or grandkids to help me interpret computerese)) would be appreciated.Thanks.

Fact: The Truth of the Canjoe Instrument History

As I've got a lot of guitar making work on, and need to get some custom builds finished, also with loads of guitar shows to prepare for, I'd been thinking about improving my efficiency with slotting fretboards. I'd already recently built my second manual cutting jig, which uses an master template and an indexing system, but it's still quite a drag slotting fretboards, so after much consideration and pondering. I decided that I needed to get a table saw. Buying workshop power tools is always a problem I feel, as unless you have a huge budget, it's very difficult to get the right tool at the right price. You can get all sorts of bandsaws, table saws and thicknessers etc at attractive prices, but inevitably they are flimsily built and underpowered..and I've learned it's always better to buy something with more capacity than you think you'll need.

I'd looked all over eBay for weeks, but the used stuff that was on there was not going cheap, and generally speaking was cheaply-made junk. I've never had table saw before, but did some research, and decided I REALLY needed a small but robust machine....that's not easy to find. The main criterion for robustness was a cast iron table...and that's what takes the saw out of the budget category. Most cheap saws have inaccurate extruded or cast aluminium tables, or even worse, pressed steel tables..with flimsy pressed steel or even plastic enclosures. I found one that fitted the bill..it wasn't exactly within my budget, but I'd had a good day at the Northwest Guitar Show, so decided to plough some of my profit back into the workshop. It's an Axminster "Hobby" saw..but don't let the description fool you, it's a robust little beast...weighing in at a monster 55kg (120 lbs!!!) ...that's the cast iron for you. It is amazingly quiet, as it has an induction motor..and I suspect the motor contributes a lot to the weight...and the cost.

I had to buy a fret slotting blade (not cheap) and I also splashed out on a template so I can slot 25 1/2" and 25" scale fretboards. I've made a "sled" which slides over the table, and got a bit sophisticated with it so I can raise the indexing pin, so that as well as just slotting standard1/4" thick fretboards, this also allows me to slot direct into the top of a one piece neck blank.

I was happy slotting fretboards manually, one by one, and it's quite easy to make a jig...but when you get to making 10 guitars per week sometimes...it can become quite a task. So, hopefully, this is going to speed up getting through those back-orders..and by the way, if you need a slotted fretboard, you can now buy one from me!! Head over to my website and look in the Chickenbone John online shop

So I just won this "Rare 1925 Collectible Uncle Jakes Nickle Seegar Lined Wood Cigar Box". I got a screaming deal on it!

It's 13"x8"x3.5". Really a perfect size for a guitar. But should I turn it into a guitar or hold on to it to resell? I don't collect cigar boxes, but I love a deal.

The other issue is the top / label. I'd have to cut into it for sound holes. I'm not opposed to this. I think it would make a super cool instrument, especially if I can source some old wood for a neck.

What are your thoughts?

Taking suggestions on this one too - not antique but somewhat rare: