How I Wind Low and Medium-Z Pickups On the Cheap

CAUTION: I do not wish to pretend I know what I am doing. But this is what I am doing...

You can hear them on my videos.

----------

What NOT to do:

Let's get this out of the way. Do NOT do this.

Make sure your desk is clean and free of metal shavings or STEEL WOOL. I learned of this hazard from a video done by Dylan of Dylantalkstone.com. As I watched that, it occurred to me that I had just finished taking pictures of winding a pickup, with steel wool in the background. THANKS Dylan. He pointed out what should have been obvious to me. This pickup is still alive now, but I can't help but think of Schrodinger's cat when I play this pickup's guitar...

The Project

I wanted to approach this experiment as I thought someone who had nearly nothing but a few tools and junk to work with. Being a somewhat poor boy myself, I had to compromise on a few things. I wanted to attempt to not only build my first pickup with a cobbled together winder, but do it as cheaply as I could. Better still would be to build the first one with things I had already at the house. I also wanted to do this as primitively, within reason, as I could.

First off, I built a platform that I could clamp to a larger surface, such as a table or bench. I had this scrap wood and a little MDF and did some gluein' and screwin' it together. I took a manual hand drill I had laying aand just nailed and screwed the drill to the platform with a metal strap and some old screws I had laying around. I used a half-dull ten-year old Stanley miter saw in the spirit of things. I then assembled it using more old screws and glue. never intended this thing to make more than one pickup. I'm a bit of an amature blues history buff and I kinda wanted to simulate what an old sharecropper/bluesman that had an unexpected pickup failure at a house party might do. Deal with what he had. That was the whole point of this exercise. To see if it was an exercise in futility for me, or if I could make it work. I guess corporate America calls it "feasability study". I call it fun. After probably two-dozen pickups, including single-pole diddley bow pups and odd-ball configurations. Almost all of them made noise. And I learned. Boy howdy! Did I learn.

A word of caution here. I have seen several people online that use a rechargeable screwdriver or drill motor for winding. I have often wondered how many got halfway through and the drill motor died. Sounds like an aggravation I don't need. Murphy seems to find me too often.

I had an old empty teflon spool laying around and drafted into service for spooling up the wire. I cut a small piece of scrap wood into a square so it would fit in the hole tightly and drilled a small hole through the center and press fit it. That's where the spindle goes. I built a few different forks to hold the spindle and the wire spool before I settled for one.

Winding It All Up

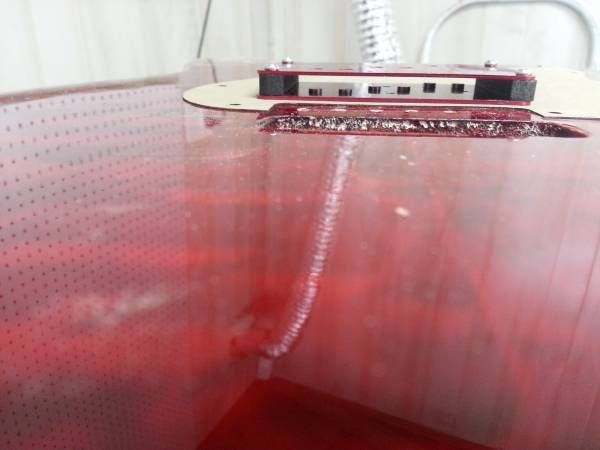

As you can see above, the nuts/poles are stuck to the computer hard drive magnet which is stuck to the winder. I sometimes use earthquake putty to help hold it in place while winding..I usually lead off with about six inches of wire and tape it to the top of the pickup. I then wrap the core four or five times by hand. I check that everything is tight, straight and free of "FOD" Foreign Object Damage and start winding. I then wind until I run out of wire on the spool. I then tape about six inches of that end to the bottom of the pickup until I am ready to start the soldering. The pictures at the end of this builder's log will show ways of attaching the leads. I have yet to settle on one method as they all have their own unique value and their own limitations and difficulties. If I find one "better" way, I'll post at a later date.

Pickup

My last pickup build was 800 winds of 34 gauge wire from a large 12v Wall wart. I got just under 100 ohms resistance from that. Took me about 20 minutes of winding with frequent quick breaks for a sip of coffee and make sure everything was tight and straight.

I now usually take off-cuts from the neck of the guitar to make the top and bottom of the pickup, if I have any big enough. File and sand and sand and sand the wood slices down to 600 grit to make them ultra smooth. Even the slightest sliver in the wood WILL catch the wire and it can get messy real quickly. I didn't always notice when one got caught on something at or near a corner before I wound a dozen winds over it. I just gently got the wire off the snag and wound wire over it. They still work, so... If you break the wire halfway through the wall-wart, well, try not to. I typically get between 300-800 winds per transformer. Mine get from roughly 50-100 ohms, so you don't have much headroom for mistakes. Luckily, 34 gauge wire is a LOT harder to break than 42 or 43 AWG! I generally use the wire that's between 31-35 AWG from the wall-warts. That's probably why these are fun to wind. Thicker wire = stronger. I have no experience using "proper" pickup wire, but hope to try that someday. I did get some .0035 from one wall-wart, but I dropped it ten seconds after I finished it. SOB! WHY ME!!! WAHH! NOTE: These things don't like to be dropped four feet onto concrete. No amount of whining, cursing, or crying will make it good. I know. I tried all, in that order.

Poles are usually stainless machine screws of various lengths. If you go this route, make sure they have enough ferrous material in them to be strongly attracted by a magnet. Some stainless has no magnetic attraction. I've built with 3/8 - 1 inch screws. I either slap a computer hard drive magnet on the bottom of the nuts or put neodymium button magnets on the bottom of poles. In one, I drilled holes in the neck under the pickup in alignment with the poles and glued the button magnets flush into the neck. Then the pickup was mounted to the top just above magnets. .015 in.? Looking forward to trying real guitar pickup magnets some day. Thousands of possibilities...

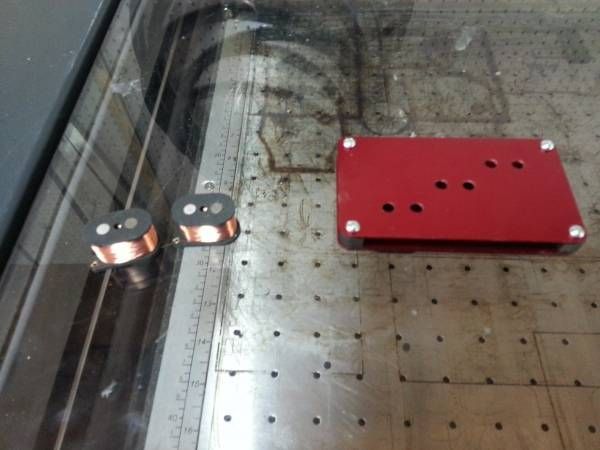

Some of my first experiments. One is still in a guitar and still working.

I have not wax potted any of the pickups that I have built, and fortunately, I haven't regretted it. I have yet to have much in the way of microphonics in any of the pickups, (tiny amount in some...), except for one that I brushed nail polish on the coils about every couple of dozen or so turns. That one is quite microphonic. It's not even the most powerful. Go figure.

I also twist the lead wires before installation to reduce the chance of interference. With the very low-z, there is already a VERY clean signal produced by the pickup. Some, I have read don't like the sound, but I found that an added buffer, or other type of boost will add color and distortion. A preamp works nicely here... I can plug our BR-600 into it before sending the signal on to our amp and it sounds more like a more conventional pickup, but cleeeeaaan unless effects are added. Or, just add a ton of gain and crank it.

Building the bobbin would be a lot easier if I could get some thinner hardwood stock, but I am using what I have... (obligatory grumble) I usually cut the top and bottom from 1x2 hardwood, often part of the neck. I cut them to the size that I want + about .02 inch in for tolerance. I file or shave the edges to fit the hole in the box when installing. I also build a wooden core. I usually cut the wood with a little excess to file away to give you tolerances for the drilling of the three holes for the poles. If you have a drill press, I would use it here. Make this puppy smooth. I used a little bit of glue to hold the wood core to the top and bottom, taking care to clean up any that oozes out of the gaps. This should help keep the wires out of any tiny gaps that might be there between core and top and bottom. I drill the holes for the poles a bit undersized. I like the screws to be just a bit tight when the whole thing fits together.

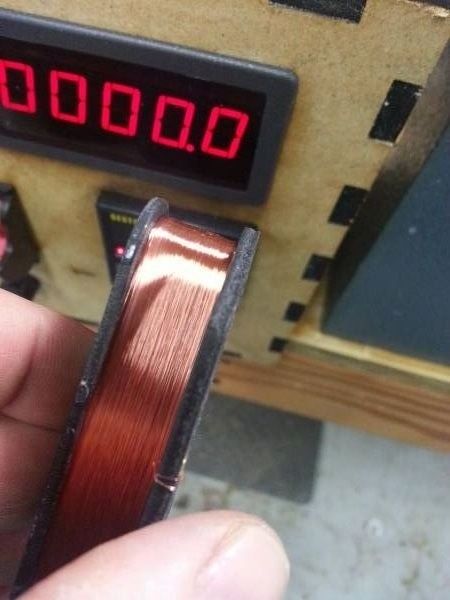

The Coil Wire

There are a lot of sources for enamel wire out there, electric motors, solenoids, relays, etc.. I mostly have experience in taking apart wall-warts because it was the easiest way to access it that I tried. I never came up with an easy way to take one apart other than learning that the plastic case of the wall-wart breaks easier if it is cold. Cold garage works well, but summer probably won't offer much of that... You can put it in your freezer for an hour or so before bludgeoning it to death if you wish... There are several videos out there on how to take them apart. I don't have any pictures of this process and I don't have access to an old, unused transformer right now. I put the transformer on the anvil of my vise with the seam placed vertical and whack it along the seam. Be careful doing this. If you don't crack the housing, when you hit it, a light hammer can come back at you, fast! Once you get the cover off, it's relatively easy to see what needs to be done, there is no easy way, I use a chisel to start the outside leafs of thin sheet steel to tap them out of the plastic frame. Once the thin plates start coming out, sometimes a pair of pliers will help.

In the picture below you can see the wood hub I made that goes through the transformer frame. Then place the thing into the wood yoke so it can spin freely while giving up it's wire to the teflon spool. If you have any questions about this or anything else, please ask.

The Connection

My skills at soldering are about average when it comes to automotive-sized wiring, but I have a problem with soldering electronics. First of all, there is this strange sucking noise that starts up as soon as I start to solder the enamel wire of the coil to the leads, and doesn't stop until I stop soldering... Partly because of this, I have tried quite a few tactics to master this elusive task. I can DO this, it's just an iffy proposition and I have to redo it more often than I'd like to admit. For this reason, I am going to highly recommend you do your own thing on this. You are probably more adept at it. I do know one thing. Using a disposable lighter to burn the enamel off the wire works until you get below about .007 of an inch thick, but anything less than that is likely to go up in flames. For the thicker wire, .007 to .011, (thicker wire nets very little volume of sound), I use a lighter, then very fine sandpaper 600+ grit or higher to rub off the ash. For thinner wire, I carefully use the sharpest blade I have to scrape the enamel off and/or use 600 grit and carefully rub it off.