3000+ RPM Pickup winder with Tach, Counter and autostop

I'm releasing this under the Creative Commons License - Attribution Non-Commercial Share Alike (CC BY-NC-SA)

Why build this winder?

Cost vs performance for starters. Features for another. Want to push your decision over the edge? You can build this winder for $158.00 and have a whole lot of machine for very little investment.

One of the lowest cost and most popular "Pro" winders is $462.90 and it only has a counter; no tach and certainly no autostop. You'll also need to align and tape your pickup to the front of it with carpet tape. Check it out for yourself.

Basic idea and cost breakdown

Why a lathe based winder? Safety, speed and superior winds. The lathe provides an ideal turnkey winding platform with the addition of some industrial automation components and a little know-how.

The tail stock of the lathe positions the pickup precisely on the winding plate and holds it in place securely without the need for carpet tape. There are no worries of your pickup flying off the tape and embedding itself in your face.

I've wanted a new winder for awhile, and figured I could make better than I could buy, and do it for cheaper. I reused everything I could from the basic lathe and used off the shelf components to keep this simple and inexpensive. You just program the number of turns, press go and let it rip while you guide the wire. I don’t see the need for an auto traverse, so I didn't make one; I like scatter wound PUP’s.

I wound my first pickup in 1986 - this winder incorporates everything I've learned since then and has all of the things I wished all of the other winders had :-). What does that mean? ... it means that it's a stripped down gas can built for speed and it's meant to scatterwind pickups on a professional level. It will wind a pickup in 1/4 of the time of the store bought commercial rigs based on the Schatten design, and it will wind a truer pickup. It will also get away from you and make a clown wig of your expensive wire in that same amount of time as well. Start slow and work your way up to quicker winds. The payoff for your practice? Faster winds produce tighter coils with less microphonics and you can fit more wire on the bobbin if you need to.

I also added a forward and reverse switch for CW and CCW operation so you don’t have to flip the pickup over to do a reverse wind – you can even wind stacked humbuckers without removing the pickup to switch direction between the upper and lower coils.

Most parts can be sourced from Ebay or Amazon (Ebay turned out to be cheaper); just search these descriptions –

Tachometer - 0.56" DIGITAL Red LED Frequency and Tachometer Rotate Speed Meter DC 7-12V

Preset Counter C3E-R-220 - 110V 220V 6 Preset Digital counter 10KPCS Relay

(get the 110v - 220v relay version, 12v - 24v version will require an additional 12v power supply)

From Radio Shack - DPDT center OFF switch

This source is just for convenience, just get a DPDT center off switch with spade logs.

Neon Lamp

Again, get what you want, 120V will be the easiest to use.

The following parts are from www.sparkfun.com

Photo Interrupter GP1A57HRJ00F Breakout Board

Photo Interrupter GP1A57HRJ00F

Resistor 330 Ohm 1/6th Watt PTH

For those who would like to make the winder but might have trouble making the opto interrupter disk... here's the file in a format ponoko.com likes. Just upload it to them and they'll cut you one.

Their current pricing to make if for you is $5.33, so not bad at all. Make sure to specify these options -

Acrylic - Black

3.0 mm

P1 - 181.0 mm long x 181.0 mm wide

Making: $1.83

Material: $3.50

Total: $5.33

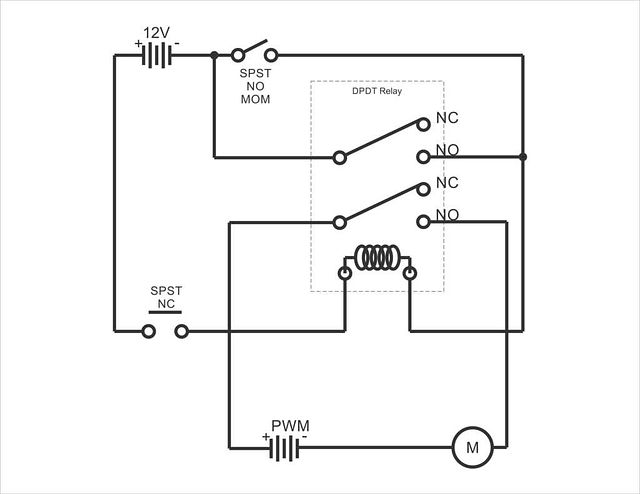

Schematic and control circuit - click to open the PDF - this is the layout to use if you're using the Harbor Freight lathe as your platform.

Theory of operation

Note:This is here for those that are interested in the how and why; it's not necessary to understand this section to build the winder. Also - this is rather conceptual in as much as the a low voltage relay is built into the counter already. You would only need to add an external relay like this one if you need to switch a large current load directly... a motor for example. Most controllers will use a low voltage trigger or inhibit line like the Harbor Freight lathe.

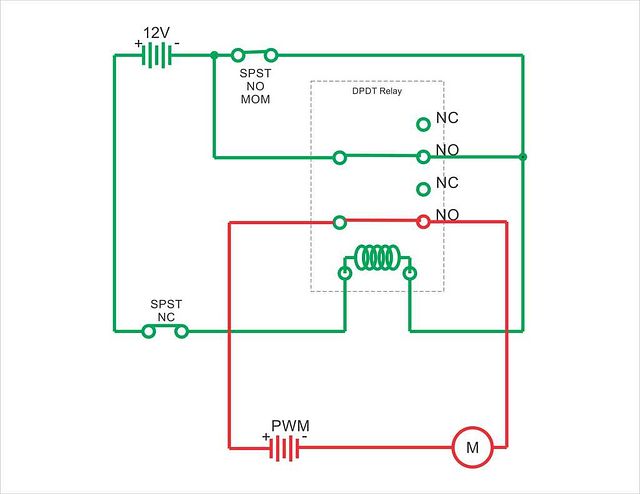

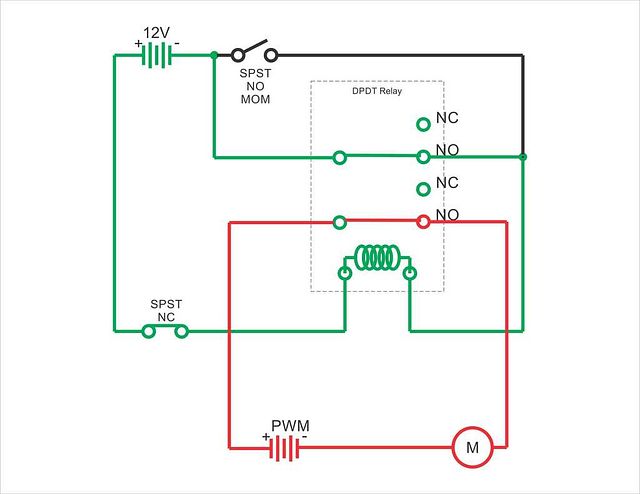

My design relies on a latching circuit for basic operation – so here’s how that works…

Here’s an animation I did to illustrate the basics of a latching circuit – you’ll find that this is directly relatable to the schematic posted below.

S1 is a momentary action switch, so it returns to it's original position after you press it, but while pressed, this is what the circuit looks like... S1 is pressed and latches the upper portion of the relay, both armatures move as one and the lower armature circuit completes the circuit between the motor and it's power supply, and the motor begins to run.

S1 is a momentary action switch, so it returns to it's original position after you press it, but while pressed, this is what the circuit looks like... S1 is pressed and latches the upper portion of the relay, both armatures move as one and the lower armature circuit completes the circuit between the motor and it's power supply, and the motor begins to run.

S1 is released, and through the nature of the circuit, the relay remains "Latched". The coil is still conducting and pulling both of the armatures into a closed condition and the motor and it's power supply are still bridged so the motor continues to run.

S1 is released, and through the nature of the circuit, the relay remains "Latched". The coil is still conducting and pulling both of the armatures into a closed condition and the motor and it's power supply are still bridged so the motor continues to run.

The momentary switch labeled S2 in this schematic represents the "normally closed" outputs of the counter's relay. Imagine that you have the counter set to spin until it reaches 10,000 winds and it gets there. The Normally closed contacts on the counters relay open, thus breaking the electron flow through the coil, thereby releasing the armatures, severing the circuit between the motor and it's power supply and the motor stops spinning. The circuit is now in a rest state and "unlatched". The circuit is reset and made ready to run again when you press the reset key on the counter, thereby closing S2.

The momentary switch labeled S2 in this schematic represents the "normally closed" outputs of the counter's relay. Imagine that you have the counter set to spin until it reaches 10,000 winds and it gets there. The Normally closed contacts on the counters relay open, thus breaking the electron flow through the coil, thereby releasing the armatures, severing the circuit between the motor and it's power supply and the motor stops spinning. The circuit is now in a rest state and "unlatched". The circuit is reset and made ready to run again when you press the reset key on the counter, thereby closing S2.

Interfacing with the Harbor Freight lathe –

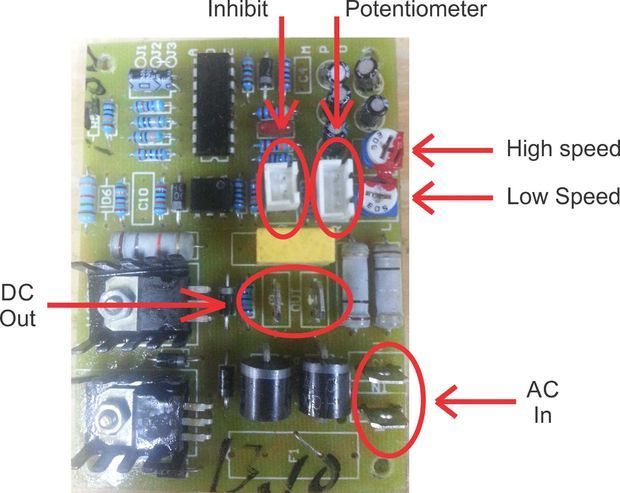

This is the motor control board for the Harbor Freight 8x12 wood lathe and probably several others.....

This is the motor control board for the Harbor Freight 8x12 wood lathe and probably several others.....

Here's how everything works -

DC out - motor for the lathe

AC in - AC input from wall (mains)

Potentiometer - (controls lathe min-max speed)

Inhibit - what we're using to stop the motor at the specified number of turns. Most commercial DC motor controllers have some variation on this theme... some provide braking and others, like this one, kill the DC voltage going to the motor. Other variations of lathes use this input for a type of safety circuit or to make sure chip guards are in place.

For some unknown reason of applied goofiness in engineering, on this lathe, this line was attached to a momentary push button switch labeled "circuit breaker reset"... whatever.

*** In this design, it's now connected to the "Normally Open" outputs on the counter module - when those outputs close when the preset count is reached, the motor controller shuts off. ***

As for the High and low speed adjustments, they do exactly what they sound like :-) - adjust the lower one to have the motor start at 0 RPM's instead of a "really not appropriate for this application" 750 RPM.

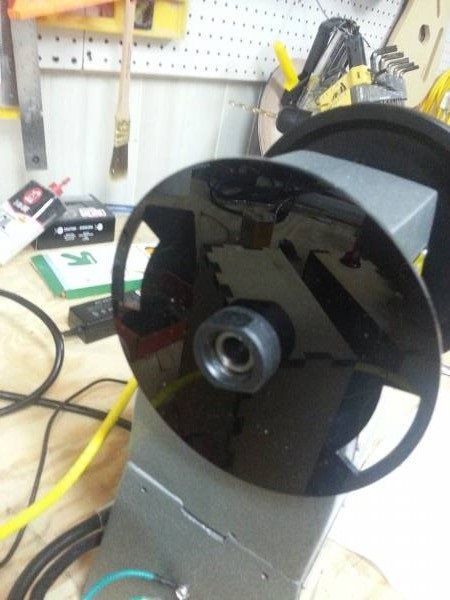

Opto interrupter disk and opto interrupter for counting winds

Here's a view of the left side of the lathe with the plastic bell housing removed showing the opto interrupter disk I cut and the assembly steps –

Spindle assembly ready for optical interrupter instillation (remove the plastic bell housing and the outer most jam nut) -

Place spacer on spindle shaft (I laser cut this spacer, but you could stack washers to achieve the same effect) -

Place spacer on spindle shaft (I laser cut this spacer, but you could stack washers to achieve the same effect) -

Spindle assembly ready to go with the new opto interrupter disk and outer jam nut installed – you need 2 windows on the disk and it needs to be well balanced, 3000 RPM is unforgiving in this area.

Spindle assembly ready to go with the new opto interrupter disk and outer jam nut installed – you need 2 windows on the disk and it needs to be well balanced, 3000 RPM is unforgiving in this area.

Under power at 3200 RPM – smooth as silk.

Under power at 3200 RPM – smooth as silk.

This photo shows the opto sensor on the top of the lathe – it just attaches with a magnet and hangs over the disk. I’ll take better pics of this area as soon as I get a chance.

The winding bar is made from 10mm stainless stock (what I had laying around). You just need a piece of round stock that will fit in the opening of the cross slide (included with the lathe).

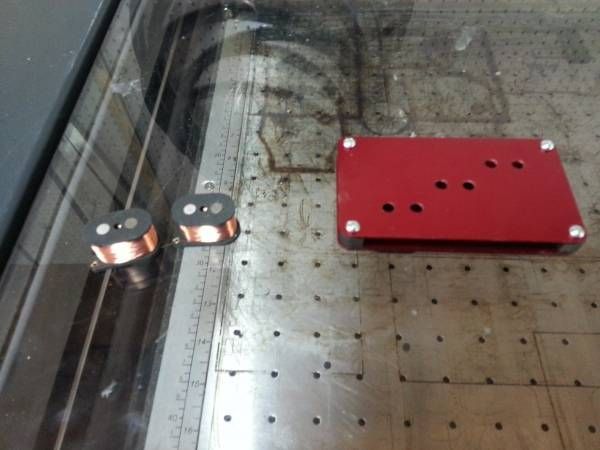

Magnetically adjustable wire guides

This innovation is kinda cool and works very, very well. The wire guides are 10mm ID ball bearings held in place and adjusted by magnets (way easier to adjust position then using set screws). Set screws are a pain, and not needed. It's super handy to be able to adjust the wire guides without fuss mid wind.

Buy ball bearings that fit your round winding bar from the previous step. McMaster Carr is a good source.

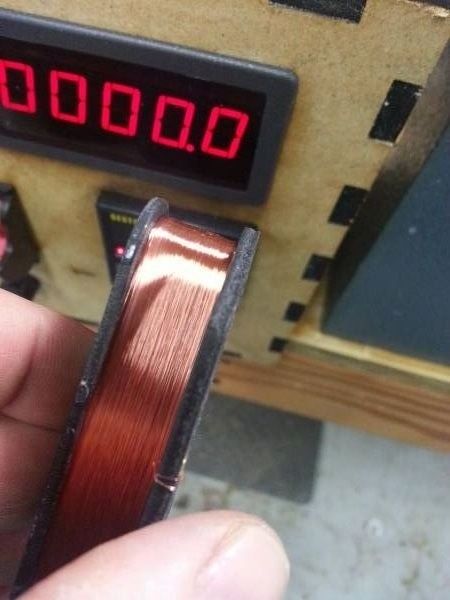

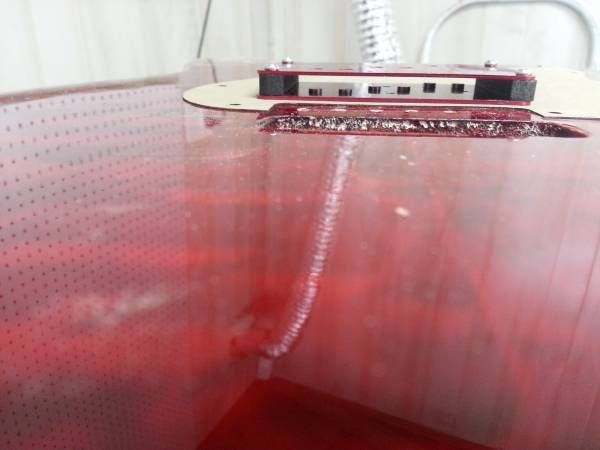

Handwound pickup goodness...

This winder is capable of producing some truly spectacular pickups - if there's interest, I'll do a start to finish on pickup making, from making the flat work from scratch (just like the ones above) to potting the pickup in wax and all points in between.

Comment

-

Comment by Andrew POWTER on November 3, 2015 at 12:51pm

-

Wow. Did anyone tell you that not every one has a lathe? Suddenly $158 turns into $358, and look at that - suddenly the Schatten pup winder looks affordable. There are better "no lathe" pup winders out there. Move along people, there's nothing to see here.

-

Comment by mojoatomic on November 3, 2015 at 12:18pm

-

Thnaks Raymond, let us know how you get on with your winder build

One word on the Arudino, if I may (may save you some heartache) - you will find it neigh impossible to get a pulse train fast enough to move the stepper at a reasonable velocity for winding :-(

-

Comment by mojoatomic on November 3, 2015 at 12:14pm

-

Thanks Wayfinder, very generous :-)

-

Comment by Raymond Overman on November 3, 2015 at 8:12am

-

Nice inspiration. I've had some plans with an arduino/stepper powered winder in the back of my head for a while and had most of the parts in a box in the shop. This may get me off my butt to make it happen.

I don't think I'm going to mess with the electronics on my Jet 1642 though. Too much invested to mess it up.

Thanks for the great write up.

-

Comment by mojoatomic on June 30, 2014 at 2:58am

-

Thanks Rand

-

Comment by Rand Moore on June 29, 2014 at 2:35am

-

Really cool article... Keep on pushing the envelop!

- ‹ Previous

- 1

- 2

- Next ›

Recommended Links & Resources

- CigarBoxGuitar.com - the knowledgebase of the homemade music movement.

- Cigar Box Music - How-to-Build CBGs DVDs, How to Play CBG and more!

- 3-String-Guitar.com - John "Red Dog" McNair's unique take on cigar box guitars and their history - lots of historic photos!

- The Cigar Box Guitar Manifesto - the mission statement and rallying cry for the Cigar Box Guitar Revolution.

Forum

UK - Best Place to Buy Cigar Box's

Started by Rich Butters in Building Secrets, Tips, Advice, Discussion. Last reply by Crazed Fandango 1 hour ago. 1 Reply 0 Likes

Busking Songs...

Started by Nomad Jack in Performances, How to Play, Lessons, Concerts. Last reply by J. D. Woods yesterday. 7 Replies 2 Likes

Joseph J. Rogowski about Current Based Pickup Design

Started by Moritz Voegeli in Building Secrets, Tips, Advice, Discussion. Last reply by Southern Ray on Monday. 6 Replies 2 Likes

crossover guitar.

Started by Timothy Hunter in Other stuff - off topic, fun stuff, whatever. Last reply by Timothy Hunter Apr 10. 14 Replies 3 Likes

Flat bucker under box top. Any Success?

Started by Tom T in Building Secrets, Tips, Advice, Discussion. Last reply by Southern Ray Apr 9. 9 Replies 0 Likes

Has anyone tried this? Thoughts?

Started by Southern Ray in Building Secrets, Tips, Advice, Discussion. Last reply by Southern Ray Apr 4. 7 Replies 1 Like

just came accross this pickup idea on youtube.

Started by Timothy Hunter in Building Secrets, Tips, Advice, Discussion. Last reply by Southern Ray Mar 27. 1 Reply 2 Likes

VIDEO: Building a CBG with limited resources.

Started by Taffy Evans in Building Secrets, Tips, Advice, Discussion. Last reply by Southern Ray Mar 10. 1 Reply 3 Likes

Free PDF Download: Vintage Guitar Effects Plans - 1967 Fuzzbox and 1969 Treble Boost

Started by Cigar Box Nation in Feature Articles. Last reply by BrianQ. Mar 9. 4 Replies 3 Likes

Tune up songs

Started by Ghostbuttons in Building Secrets, Tips, Advice, Discussion. Last reply by Timothy Hunter Mar 9. 5 Replies 1 Like

Duel output jacks

Started by Justin Stanchfield in Building Secrets, Tips, Advice, Discussion. Last reply by Taffy Evans Mar 8. 6 Replies 0 Likes

No Harmonics

Started by Ken I in Building Secrets, Tips, Advice, Discussion. Last reply by Brian partington Mar 8. 8 Replies 0 Likes

Camera suggestions?

Started by Southern Ray in Cool gear discussion - that's not cigar box related. Last reply by Southern Ray Mar 6. 5 Replies 0 Likes

CBG site issues, continued.

Started by Taffy Evans in Other stuff - off topic, fun stuff, whatever. Last reply by Taffy Evans Mar 5. 4 Replies 2 Likes

Anyone used a violin-style tailpiece on a CBG?

Started by Justin Stanchfield in Building Secrets, Tips, Advice, Discussion. Last reply by Carl Floyd Mar 1. 15 Replies 0 Likes

Guitar for the grandson

Started by Joe in Performances, How to Play, Lessons, Concerts. Last reply by Carl Floyd Feb 29. 13 Replies 0 Likes

Building with vintage paper/pressed board cigar boxes.

Started by Chance in Building Secrets, Tips, Advice, Discussion. Last reply by Southern Ray Feb 22. 12 Replies 1 Like

How to Get Your Own Music on Spotify

Started by Cigar Box Nation in Feature Articles. Last reply by Southern Ray Feb 21. 2 Replies 4 Likes

Trash Canjo

Started by Brad in Cool gear discussion - that's not cigar box related. Last reply by Southern Ray Feb 19. 6 Replies 3 Likes

Do Measurements Matter?

Started by Jacob Shook in Building Secrets, Tips, Advice, Discussion. Last reply by Southern Ray Feb 16. 10 Replies 0 Likes

Blog Posts

I'll be fashionable this summer =)

Posted by Vlad on March 31, 2024 at 11:48pm 0 Comments 1 Like

Everyone can make CBG. And I did it =)

Posted by Vlad on March 6, 2024 at 2:32am 5 Comments 2 Likes

.✨. Cover Me ..♪♫•*¨*•. ~ the Delta Blues Outlaws

Posted by billy jones bluez on February 28, 2024 at 2:09pm 0 Comments 0 Likes

Q&A with Arkansas-based talented blues musician Billy Jones, one of the very best authentic modern artists

Posted by billy jones bluez on February 17, 2024 at 11:00pm 0 Comments 0 Likes

Big Power Bank for Small CBG =)

Posted by Vlad on February 11, 2024 at 1:06am 1 Comment 1 Like

Latest Activity

UK - Best Place to Buy Cigar Box's

Up the Hill A D Eker 2024

Off the Bench !

CigarBoxGuitar.com Knowledgebase Articles

Events

Music

© 2024 Created by Ben "C. B. Gitty" Baker.

Powered by

![]()

Cigar Box Nation is presented by C. B. Gitty Crafter Supply, your one-stop-shop for Cigar Box Guitar parts and accessories!

You need to be a member of Cigar Box Nation to add comments!

Join Cigar Box Nation